Supply Chain Management

The Company engages in business operations and implements corporate social responsibility based on the principles of integrity, trust, and innovation. The Company values energy conservation and carbon reduction and biodiversity and pays close attention to risk factors such as climate change to create long-term stability in the supply chain.

The Company aims to lead upstream and downstream suppliers to move forward together to improve, integrate and create high-quality products and green supply chains. We shall continue to work together for a better life and environment and for common prosperity and sustainable development.

* YFY Consumer Products was the first company in Taiwan to obtain FSC COC certification

| Management Regulations | Methodology | Basis and Standards | |

|---|---|---|---|

| Economy |

|

|

ISO 9001 |

| Environment |

|

|

SDS ISO 14001 |

| Society |

|

|

National regulations |

供應商的環境、社會、職業安全衛生評估請參考永續報告書「供應鏈管理篇」。

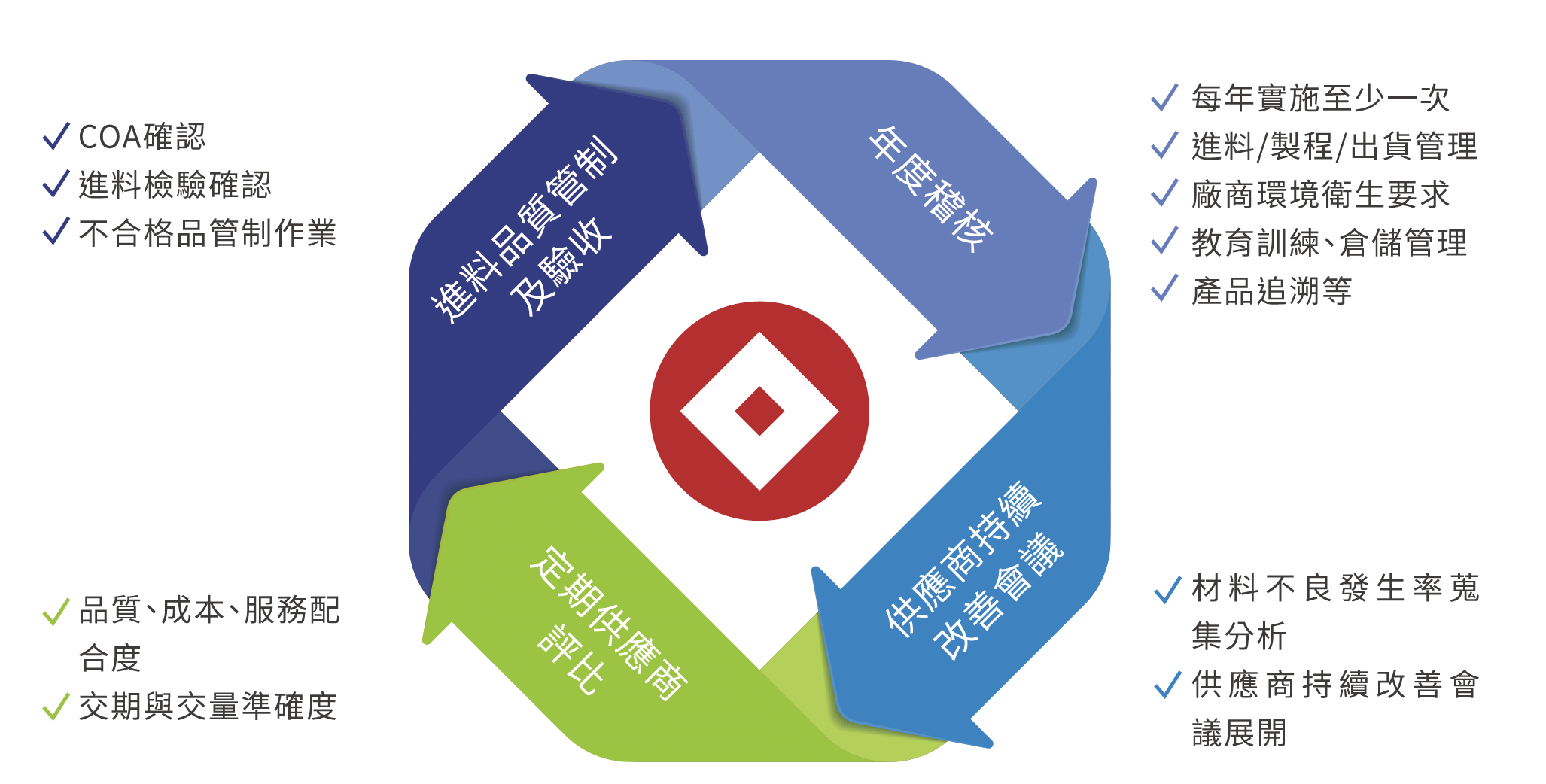

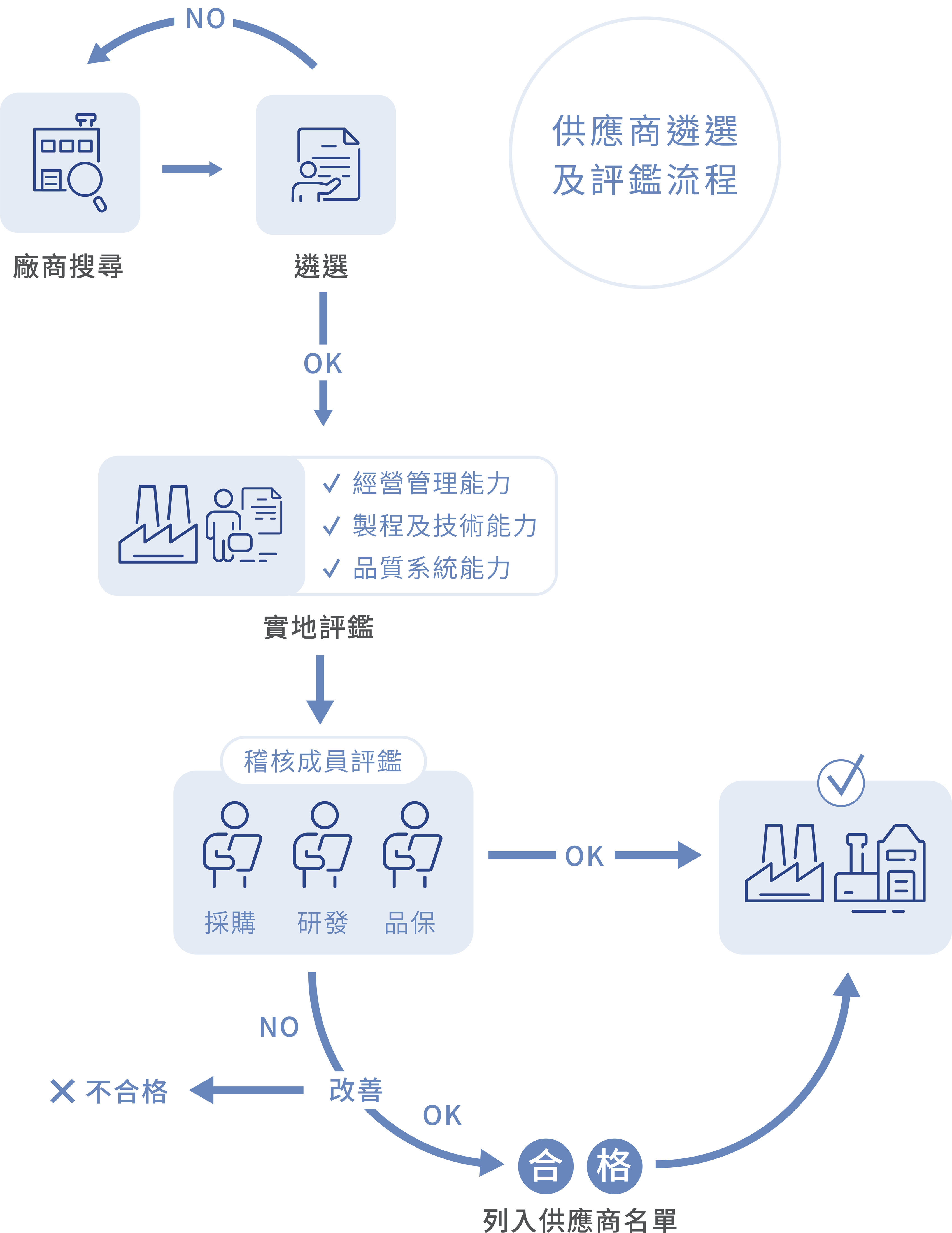

Supplier management activities are processed in accordance with the standards established and recognized by R&D units. We thus regulate the consistency and stability of our suppliers’ output quality and the Company’s inspections for incoming materials.

The Company also continues to conduct annual audits and regular performance evaluation activities to monitor and communicate with suppliers regarding their performance in terms of “quality”, “cost”, “delivery schedule”, and “services” as well as continuous improvements to ensure that products provided by suppliers meet the Company’s requirements.

- In 2022, 5 new supplier evaluations were completed, with 5 passing. The pass rate reached 100%

- In 2022, 31 annual supplier audits were completed, with 30 passing. The pass rate reached 97%

- In 2022, 467 regular supplier assessments were completed, with 467 passing. The pass rate reached 100%

YFY Consumer Products has several suppliers and plans to develop new suppliers as secondary suppliers for the development of products or services with superior features based on consideration for cost, delivery schedule, quality, or other factors.

We take into account performance, timeliness, and cost to avoid high financial, operational, production and technical risks of new suppliers. Procurement units are required to collect information and formulate risk analyses as reference for whether related units may initiate cooperation.